With over 40 years of expertise in supply chain management, procurement, global sourcing, and manufacturing, JUMA Industries Inc. leverages its extensive experience to offer innovative solutions to customers who may not have previously explored international sources. We bring a wealth of knowledge that opens doors to the myriad benefits international collaboration can bring to their operations, facilitating global business expansion. Our unwavering commitment is centered on precisely executing to our customers' needs and exceeding their expectations. Explore the world of possibilities with JUMA Industries Inc. as your trusted partner in global growth.

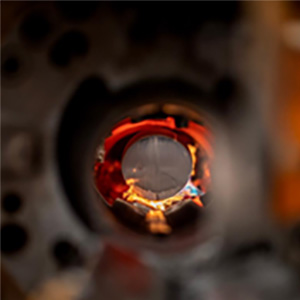

With over 35 years of experience in aluminum extrusion. our services encompass the entire process, starting from the design and manufacture of the die/mold, through the extrusion of profiles, to additional treatments such as anodizing, painting, and sublimation.

AT JII we pride ourselves on being at the forefront of delivering unparalleled nearshore and supply chain solutions tailored to meet the diverse needs of our valued customers. With a relentless commitment to excellence, innovation, and client satisfaction, we stand as your trusted partner in navigating the ever-evolving landscape of global business.

Providing comprehensive fabrication services at our facilities located in Juarez, Chihuahua, Mexico, offer a complete range of capabilities. These include fabrication, machining, metal stamping, powder coating, galvanizing, and the advanced dicronite process.

-Spanish Manufacturing Press -1600 Ton -6″ Ingot Diameter -7″ Outlet -Cooling table 45 linear meters with cooling system -Automated puller -Double cradle press at die change -Hydraulic circuits controlled by PLC -Fully automated press -22 M / 72 ft long temper oven -Powder Coat Line -9m /30 ft long anodizing tanks

-Korean Manufacturing Press -1800 ton -7″ Ingot diameter -8″ Outlet -Cooling table 40 linear meters with cooling system -Automated puller -Double cradle press at die change -PLC Controlled hydraulic circuits -Fully automated press

-Italian Manufacturing Press -2200 Ton -8″ Ingot diameter -11″ Outlet -Cooling table 70 linear meters with automated water-air system -Double puller with saw cut on the fly -Heat treatment furnace 24 meters long -Double cradle press at die change -Hydraulic circuits controlled by PLC -Fully automated press, auxiliary equipment and stocker -65 M / 213 Ft Long Temper Oven

-Whether it's metal or plastic components, we tailor our manufacturing processes precisely to meet the unique needs and specifications of each customer. Your satisfaction is our priority, and we take pride in consistently delivering top-notch products that align seamlessly with your requirements. Choose our machining services for reliability, precision, and cost-effectiveness in every project.

-Cut to length -Mitering -Custom CNC Machining -Drilling, Tapping, and Counter-Sinking

-Standard alloys: We have 6061, 6063, 6005, 6105, other alloys available upon request. We can treat your alloy to the desired tempering. Some available tempers TF, T1, T52, T5, T6,T61.

-With over 50 years of experience anodizing. Where precision meets excellence in anodizing solutions. Our facility is proud to introduce an anodizing process that stands above the rest, featuring tanks capable of accommodating lengths of up to 30 feet. As a leading provider in the industry, we combine cutting-edge technology with unparalleled expertise to deliver superior anodizing results for your components. Experience the perfect blend of efficiency, precision, and quality in every inch as we immerse your projects in a transformative anodizing experience.

-Our machining shop is strategically outfitted with a range of cutting-edge machinery, enabling us to conduct various precision operations, including milling, lathing, CNC machining, EDM (Electrical Discharge Machining), heat treatment, and grinding. This comprehensive setup allows us to deliver high-quality machining services at a competitive price point. Whether it's metal or plastic components, we tailor our manufacturing processes precisely to meet the unique needs and specifications of each customer. Your satisfaction is our priority, and we take pride in consistently delivering top-notch products that align seamlessly with your requirements. Choose our machining services for reliability, precision, and cost-effectiveness in every project.

-Our galvanizing process lines are meticulously designed to guarantee the proper handling of all materials, resulting in a finish that boasts exceptional resistance to corrosion, reduced abrasion and wear, heightened resilience to temperature variations, and an enhanced metallic and cosmetic appearance. Our galvanizing services encompass a variety of finishes, including zinc barrel, rack zinc, silver, black oxide, anodized, gold, nickel, electroless nickel, electropolish, tin, and copper. We cater to a broad spectrum of sizes, ranging from small hardware components to larger parts, ensuring the versatility and comprehensive coverage of our galvanizing capabilities.

-We specialize in crafting diverse parts and structures tailored to meet our customers' specific needs. Our comprehensive capabilities encompass various metal fabrication processes, including MIG and TIG welding, Oxyfuel cutting, and expertise in working with both steel and aluminum.